Conveyance Systems

What Are Conveyance Systems?

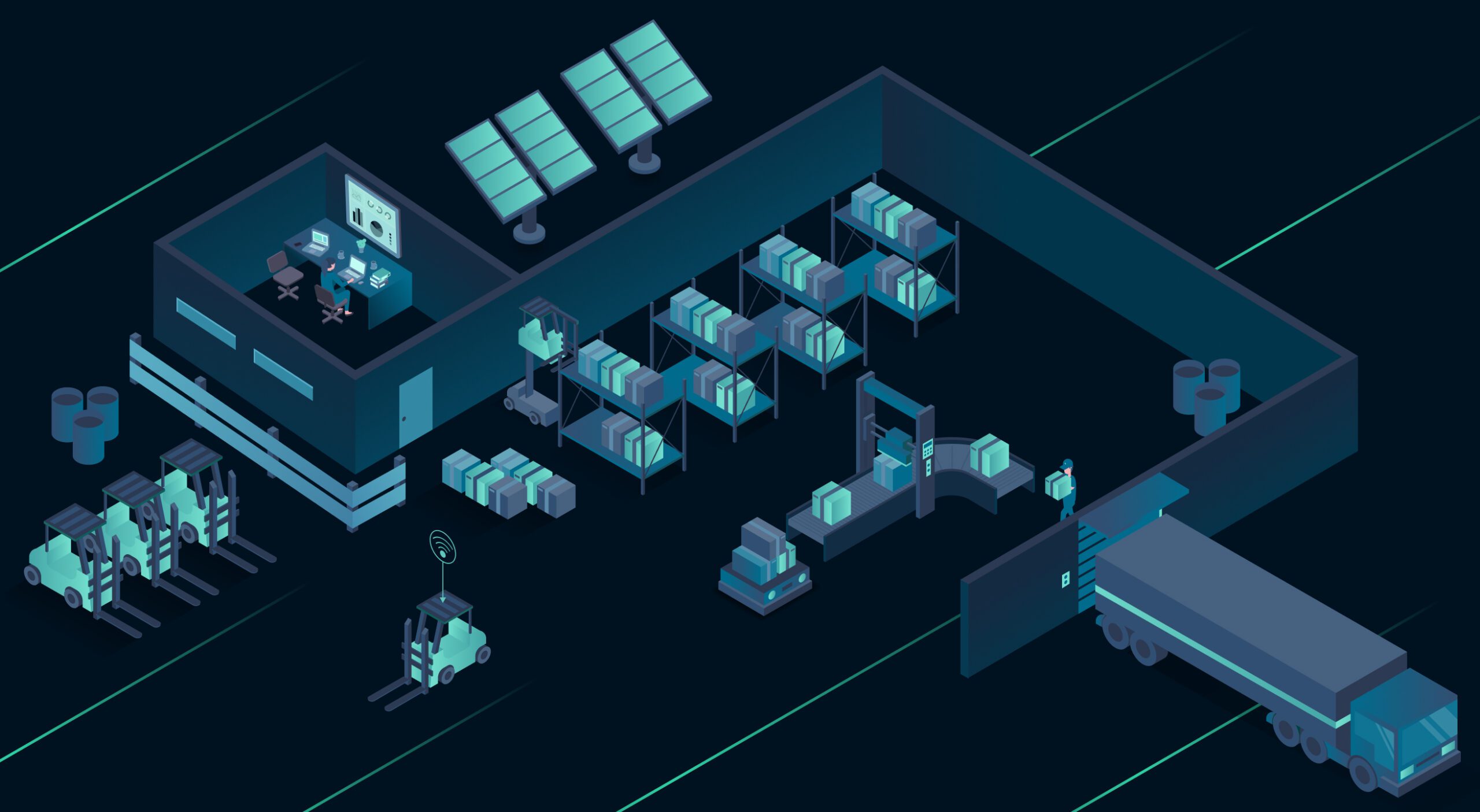

Conveyance systems are mechanical solutions that move goods efficiently within a facility. These systems are designed to reduce the need for manual handling, minimize errors, and maintain a consistent flow of materials. Whether you’re operating a small warehouse or a large distribution center, conveyance systems can be customized to fit your space, throughput requirements, and operational goals. By automating the movement of goods, businesses can significantly reduce labor costs, improve safety, and increase overall efficiency. Conveyance systems can be powered or gravity-driven and are a foundational component of modern intralogistics and play a vital role in warehouse automation strategies.

Types of Material Handling Conveyors

-

Belt Conveyor SystemsBelt conveyors are among the most versatile and widely used systems in the industry. They use a continuous belt to transport items of various shapes and sizes, making them ideal for moving boxes, totes, and irregularly shaped goods. Belt conveyors can be configured for horizontal or inclined movement and are suitable for both light and heavy-duty applications.

Common Applications:- E-commerce fulfillment centers

- Packaging and assembly lines

- Order picking and sortation zones

-

Gravity Roller ConveyorsGravity roller conveyors rely on gravity to move items along a series of rollers. These systems are simple, cost-effective, and require minimal maintenance. They are ideal for areas where powered movement is not necessary and are often used in temporary or flexible layouts.

Common Applications:- Shipping and receiving areas

- Manual sortation zones

- Temporary workstations

-

Powered Roller ConveyorsPowered roller conveyors use motors to drive rollers, offering precise control over speed and direction. These systems are ideal for automated sortation, accumulation, and merging applications. They can be integrated with barcode scanners, sensors, and warehouse management systems for enhanced functionality.

Common Applications:- High-speed distribution centers

- Automated packaging lines

- Integration with robotics and AS/RS systems

-

Modular and Flexible ConveyorsModular and flexible conveyors offer the ability to reconfigure layouts quickly, making them ideal for facilities with changing workflows or seasonal demands. These systems are easy to install, relocate, and expand, providing long-term adaptability.

Common Applications:- Seasonal operations

- Pop-up fulfillment centers

- Dynamic warehouse environments

- Inbound and outbound case/parcel handling

-

Spiral Conveyor SystemsSpiral conveyors move goods vertically in a compact footprint, perfect for multi-level operations. They use a continuous belt or rollers arranged in a spiral to transport items between floors, saving space and maintaining high throughput.

Common Applications:- Multi-story warehouses

- E-commerce fulfillment centers

- Packaging and sortation lines

- Operations that leverage mezzanines

-

Overhead Conveyor SystemsOverhead conveyors suspend items from above, freeing up valuable floor space. They’re commonly used in manufacturing and assembly environments to move parts, garments, or products along a defined path. These systems can be powered or gravity-fed.

Common Applications:- Automotive assembly lines

- Garment handling in retail logistics

- Paint and finishing operations

Benefits of Conveyor Systems

Implementing a well-designed conveyor system can have a transformative impact on your facility’s performance. Key benefits include:

- Reduced Manual Labor: Automating material movement reduces physical strain on workers and minimizes the risk of injury.

- Increased Throughput: Conveyors maintain a continuous flow of goods, reducing bottlenecks and improving order cycle times.

- Improved Accuracy: Automated systems reduce human error, especially when integrated with scanning and tracking technologies.

- Optimized Space Utilization: Vertical and overhead conveyor options help maximize floor space in tight warehouse environments.

- Scalability and Flexibility: Systems can be expanded or reconfigured as business needs evolve.

Why Bailey?

Bailey is your trusted partner for material handling solutions across Tennessee, Kentucky, Virginia, Washington, and Georgia. With decades of hands-on experience, technical expertise, and a deep understanding of regional business needs, we help companies optimize operations, improve efficiency, and reduce downtime.

Our team delivers tailored solutions that match your facility, workflows, and goals. From warehouse equipment to automation and service, we provide reliable, high-quality solutions that support long-term success. As a family- and women-owned business, we prioritize relationships, integrity, and customer satisfaction in every interaction.

Sustainability is more than a goal—it’s a standard at Bailey. We operate responsibly, continuously seeking ways to improve environmental impact while helping your business thrive. With fast, dependable support and a full-service approach, Bailey is the partner businesses choose when performance matters.

Let’s Build Your Custom Conveyor Solution

Whether you’re upgrading an existing system or starting from scratch, Bailey is here to help. Our team of experts will work with you to design a custom conveyance solution that meets your operational goals, budget, and timeline. We offer site assessments, system design consultations, and full-service installation to ensure your project is successful from start to finish. Contact us today to schedule a Discovery meeting.