VLM – Vertical Lift Modules

What Is a Vertical Lift Module?

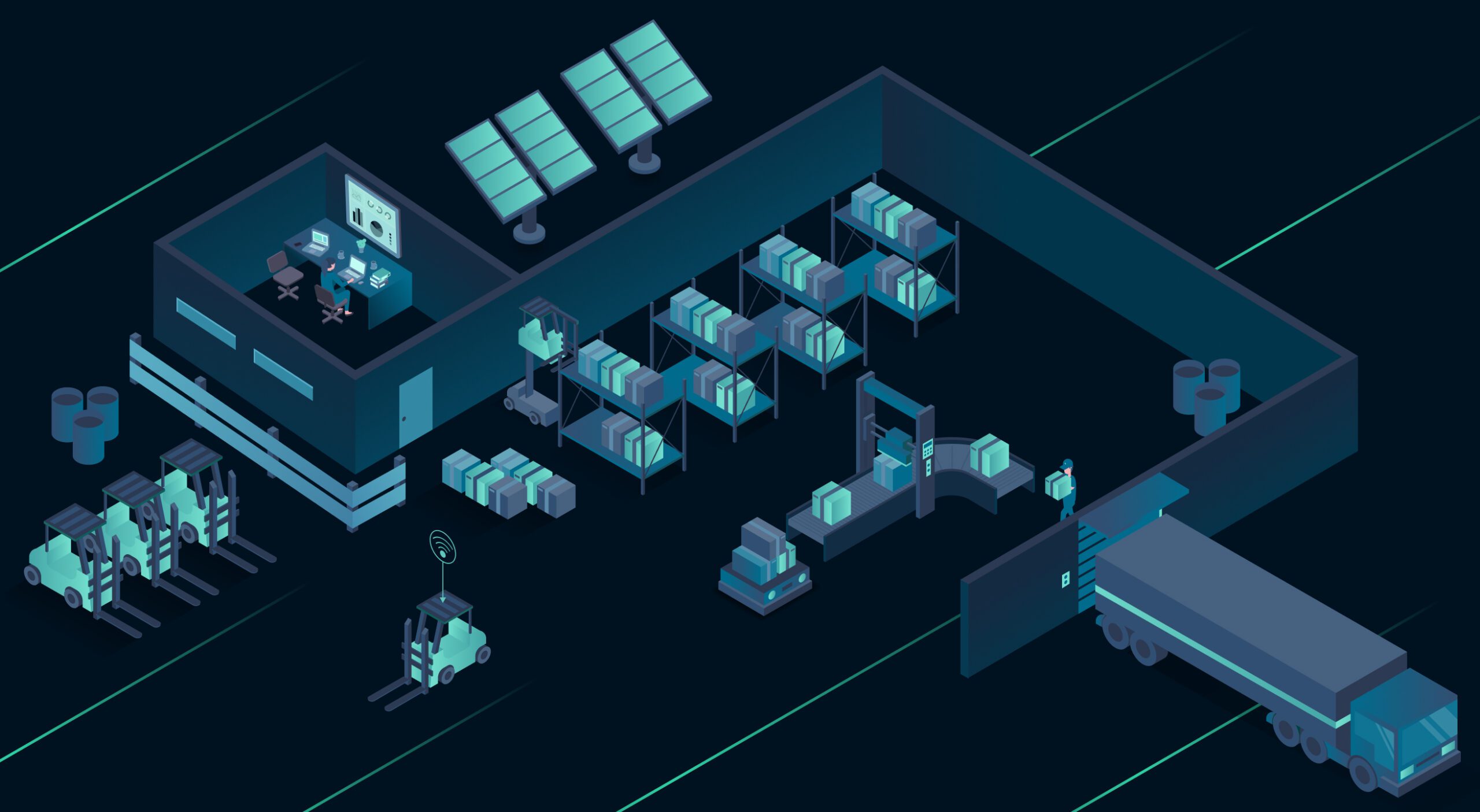

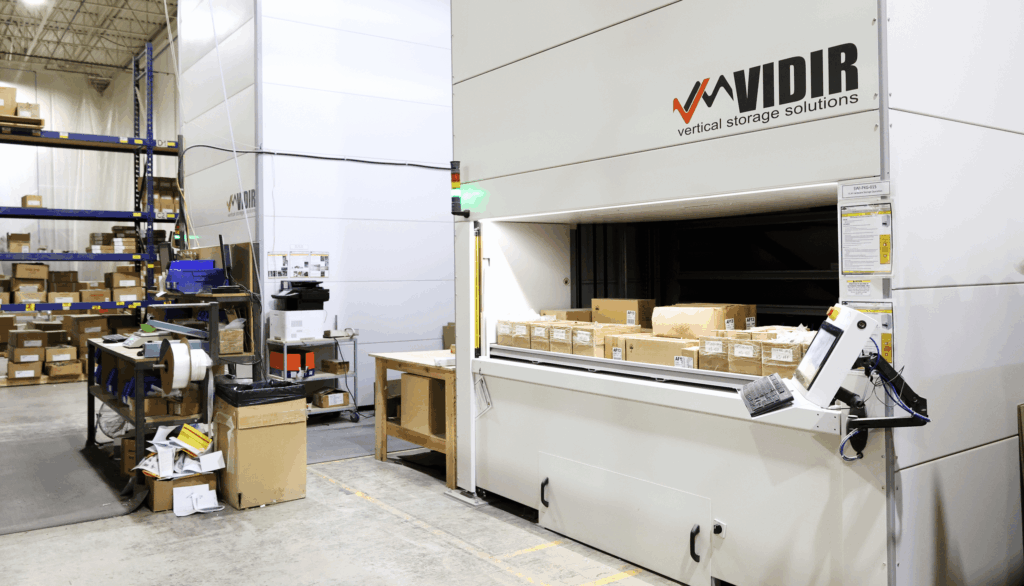

A Vertical Lift Module (VLM) is a type of automated storage and retrieval system (AS/RS) that maximizes vertical space utilization. It consists of two columns of trays and a central automated extractor that retrieves items and delivers them to an ergonomic access point. VLMs are ideal for storing small to medium-sized items in environments where space, speed, and accuracy are critical.

These systems are powered by intelligent software that tracks inventory, guides picking operations, and integrates with warehouse management systems (WMS). Whether you’re managing parts, tools, medical supplies, or retail inventory, VLMs offer a scalable solution that grows with your business.

At Bailey, we specialize in delivering automated storage VLM solutions that align with your business goals. We work with VLM suppliers including VIDIR Vertical Storage Solutions and Crown Lift Trucks. As a family-owned and women-owned company with over 75 years of experience, we combine deep technical expertise with a commitment to sustainability and innovation. Our Advanced Warehouse Solutions team is dedicated to helping you implement cutting-edge intralogistics systems that make a measurable impact.

Overcoming Power Challenges

-

01

Cost Management

Balancing initial investment and long-term operational costs. -

02

Maintenance Needs

Ensuring regular maintenance for optimal performance. -

03

Environmental Impact

Choosing eco-friendly solutions to reduce carbon footprint.

Key Benefits of VLM Systems

-

Maximize Floor SpaceTraditional shelving and racking systems often leave vertical space unused. VLMs capitalize on this by storing items in tall, enclosed units that can reach up to 30 feet or more. This can free up to 85% of your floor space, allowing you to repurpose areas for production, packing, or additional inventory.

-

Improve Picking AccuracyManual picking is prone to errors, especially in high-volume environments. VLMs use barcode scanning, light-directed picking, and software-guided retrieval to ensure the right item is selected every time. This reduces returns, improves customer satisfaction, and enhances overall workflow efficiency.

-

Reduce Labor CostsBy automating the retrieval process, VLMs reduce the need for walking, bending, and climbing. This improves safety and allows employees to focus on more strategic tasks. Businesses often see a significant reduction in labor costs and an increase in productivity after implementing VLM systems.

-

Enhance Inventory ControlReal-time inventory tracking and automated reporting help businesses maintain accurate stock levels, reduce shrinkage, and streamline reordering. VLMs integrate seamlessly with existing WMS platforms, giving you full visibility into your inventory at all times.

-

Boost SustainabilityVLMs support Bailey’s commitment to sustainability by reducing energy consumption and optimizing space. Smaller, more efficient storage areas require less lighting, heating, and cooling—contributing to greener operations and lower utility costs.

VLMs are versatile and perfect for small parts, tools, or inventory across a wide range of industries:

- Manufacturing: Store tools, components, and spare parts with precision and speed.

- Automotive: Manage parts inventory for service centers and dealerships.

- Healthcare: Secure and organize medical supplies and pharmaceuticals.

- Retail & E-commerce: Improve order fulfillment speed and accuracy.

- Aerospace & Defense: Maintain strict inventory control for high-value items.

Understanding Vertical Lift Module Cost

The cost of a vertical lift module depends on several factors, including:

- Unit height and tray capacity

- Software integration

- Customization and accessories

- Installation and training

While the upfront investment may seem significant, the long-term savings are substantial. Businesses typically see ROI through:

- Reduced labor costs

- Improved space utilization

- Increased throughput

- Lower error rates

- Faster order fulfillment

Bailey offers consultations to help you evaluate your current storage setup and determine the most cost-effective VLM solution for your operation.

Bailey proudly serves businesses across the Southeast, including:

- Tennessee

- Nashville, Chattanooga, Knoxville, La Vergne, Cookeville, Manchester, Tullahoma, Cleveland, Piney Flats, Tri-Cities

- Kentucky

- London, Somerset

- North Georgia

- Dalton, Calhoun

- And throughout the nation!

- We support clients in the Tri-Cities region of Northeast Tennessee, offering fast service and expert support wherever you operate.

Why Bailey?

Bailey is your trusted partner for material handling solutions with 10 locations across Tennessee, Kentucky, Virginia, Washington, and North Georgia—including Nashville, Chattanooga, Knoxville, London, and Dalton. Our team delivers tailored solutions that match your facility, workflows, and goals. From warehouse equipment to automation and service, we provide reliable, high-quality solutions that support long-term success. As a family- and women-owned business, we prioritize relationships, integrity, and customer satisfaction in every interaction.

Sustainability is more than a goal—it’s a standard at Bailey. We operate responsibly, continuously seeking ways to improve environmental impact while helping your business thrive. With fast, dependable support and a full-service approach, Bailey is the partner businesses choose when performance matters.

What Sets Us Apart:

-

01

Family Owned & Operated Since 1949

-

02

Certified Women Owned

-

03

The first TRUE certified Zero Waste business in Tennessee and the first TRUE certified zero waste material handling business in the nation

-

04

Advanced Solutions Expertise

-

05

Full-Service Technical Support

-

06

Strong Local Market Presence

Ready to Optimize Your Warehouse?

If you’re ready to take your warehouse operations to the next level, Bailey is here to help. Our team of experts will work with you to design and implement a VLM warehouse solution that fits your business goals and budget.